Introduction:

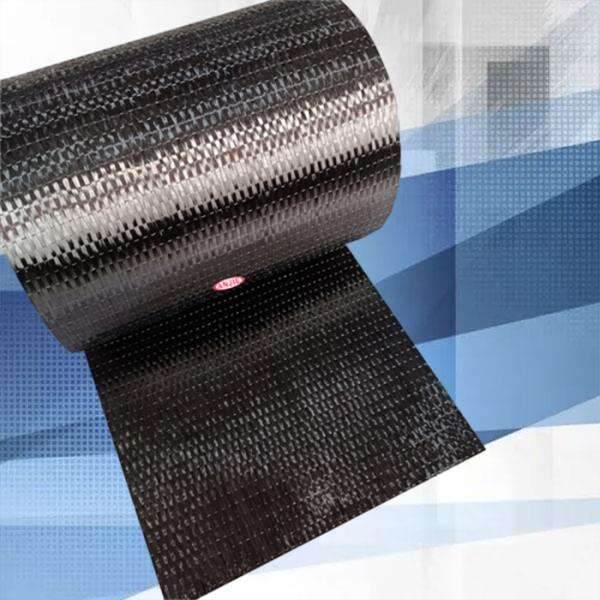

Carbon Fiber is a brilliant strong and lightweight material has been revolutionizing the real way people use materials in different industries, like carbon fiber sleeves created by anjie.

Carbon Fiber, including carbon fiber sheet by anjie has several advantages over other materials, including its strength-to-weight ratio, corrosion resistance, high stiffness, and low expansion that are thermal. These properties make it ideal for several applications, including aerospace, automotive, sporting goods, and medical equipment. Also, Carbon Fiber are highly customizable, making it perfect for custom-made designs.

Infusion molding is a relatively process new has revolutionized the usage of Carbon Fiber, same with carbon fiber reinforced sheet produced by anjie. A pre-designed mold is filled with liquid resin mixed with Carbon Fiber, and also the mixture is then remaining to cure in this process. The process results in a lightweight, strong, and uniform material can be shaped into different designs.

Carbon Fiber for Infusion Molding is a safe process will be performed in a environment that was controlled, just like the carbon fiber yarn built by anjie. The process involves mixing liquid resin Carbon Fiber, and this mixture is poured into a mold to bring shape. The procedure try monitored by trained professionals, and the mold is left to cure in a safe and managed area from any hazard.

Carbon Fiber for Infusion Molding, as well as the carbon fiber mesh fabric by anjie can be used to form designs that are very different depending on the application. The very first step to design a mold that will hold the liquid resin mixed with Carbon Fiber. The resin shall be mixed with the Carbon Fiber and poured into the mold. The mold is then left to treat to form the desired shape. After the mold has cured, it are removed, while the finished carbon to its final application.

Development research into most modern carbon fiber for infusion molding make most composite materials well as explore new applications opportunities such products regular daily activities ANJIE. Modern construction other fields require constant updates technology products. ANJIE RD team always developing new products solutions that cost-effective efficient well as most cost-effective use materials. company recently developed products often meet clients diversified application needs. Additionally, technical experts help resolve any issues may encountered during after projects' construction site. Continuous online consulting well as support materials visits projects/files, arrangements required testing etc. All these provided ANJIE.

Customer carbon fiber for infusion molding products quality assure long-term partnership potential customers, resulting becoming repeat clients. ANJIE supplying composite materials more 20 years. It ISO9001:2015 certification ISO14001 Environmentally, ISO45001 Health and Safety, SGS Factory Evaluation Report, CE Mark many certifications. products made according international standards in line ASTM standards. Products review clients rigorously evaluated respond immediately problems arise products delivered client site. ANJIE's clients around world benefit variety technical assistance. includes experienced team, product samples, solving issues using quality constant customer support.

carbon fiber for infusion molding various fiber products, which extensively utilized Construction, Retrofitting, Automotive sports, Wind energy, many other fiber composite based construction. Since 2004, ANJIE producing carbon fiber products, including carbon fiber fabric ud carbon fiber plates geo grids, fiber rebar rod as well chopped fiber so on. products utilized construction structural reinforcement. It also renowned production 3k carbon fiber carbon aramid glass hybrid fabric carbon fiber prepreg, biaxial fiber fabric, silica fiber fabric numerous others. materials widely used sports, aviation boats, other auto parts manufacturing modeling. Along materials, it dedicated facilities resin products support clients demands. From carbon fiber aramid further, ANJIE comprehensive range composite materials caters diverse applications across various industries, including aerospace, automotive, marine, construction, more.

company one largest composite material carbon fiber for infusion molding exporters. specialize basalt fibers, carbon fibers, aramid fibres fiberglass material. regularly exports world market. It home more 100 advanced machines active production line. It also dedicated QC team professional laboratory test product before each shipment. modern technologies used company ensure will able provide quality products regular basis effectively. It holds range national rewards product certifications, including ISO, SGS, CE so on. When clients require custom reliable sources products long-term client service, ANJIE would trusted partner success.

Copyright © Haining ANJIE Composite Materials Co., Ltd All Rights Reserved