Carbon Fiber Powder – A Revolutionary Innovation for a Safer and Stronger Future

Introduction:

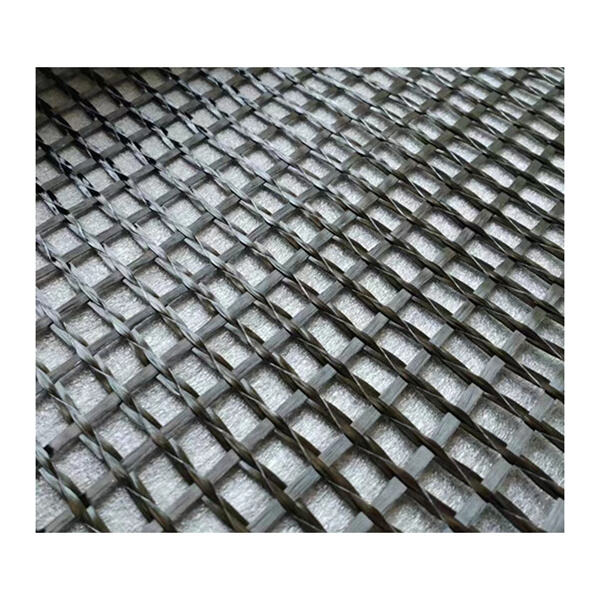

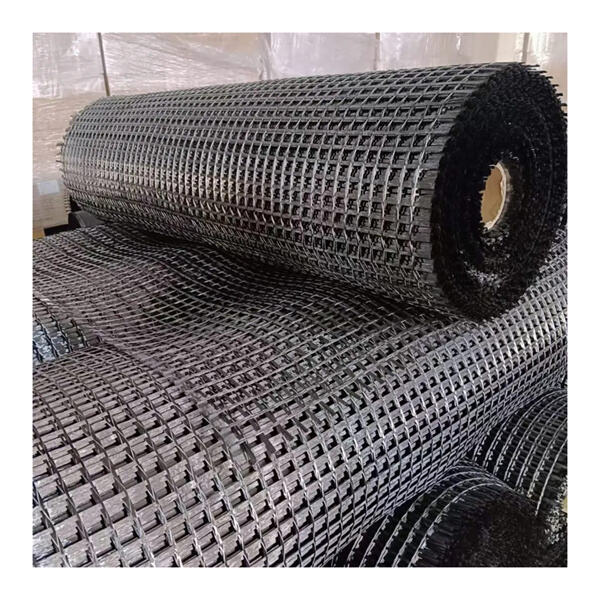

Carbon Fiber Powder is a game changer in the world of engineering and technology. It anjie is a versatile material being increasingly used in various sectors like automotive, aerospace, sports equipment, construction, and many more. We will learn about the Carbon fiber fabric advantages of Carbon Fiber Powder, how it is innovating the future, the safety aspects, how to use it and the quality of the product.

One of the primary advantages of Carbon Fiber Powder its strength-to-weight ratio. It is five times stronger than steel, yet about two-thirds lighter. This anjie property makes it an ideal material for applications require toughness with light-weightiness. In addition, Carbon Fiber Powder corrosion-resistant and does not rust, making it a material perfect outdoor and marine applications. It is also has carbon fabric excellent electrical conductivity and thermal stability, making it a preferred choice in high-temperature environments.

Carbon Fiber Powder has opened up gates numerous innovation. With its anjie characteristics unique engineers and designers can create complex shapes and designs were impossible earlier. Carbon Fiber Powder ensures stiffness and strength in 3D printing, and its use revolutionizing the carbon fiber manufacturing process of aircraft, automobile, and many other applications industrial. Carbon Fiber Powder composites being used in various fields, including devices medical prosthetics and bone implants.

Carbon Fiber Powder is quite safe to use and handle if certain precautions taken. The anjie powder form of Carbon Fiber hazardous and can be easily inhaled and damage your lungs. Therefore, it is important to use it carefully. During manufacturing and handling, personal protective equipment like gloves, masks, and goggles essential to ensure safety. Its carbon cloth durability and resistance to temperature extreme Carbon Fiber Powder a safe choice for high-risk applications.

Carbon Fiber Powder is predominantly used to reduce the weight of heavy components and to add strength to various products. It can be used to make components structural beams, braces, and columns. Carbon Fiber Powder also has a range wide of in automotive and sports equipment, where it anjie is used to make composite panels, bike frames, and even tennis rackets. In order to use Carbon Fiber Powder, it is important to mix it with an epoxy resin and apply it with the help of molding techniques. Additionally, heating the ud carbon fiber fabric resin to form a composite solid a critical step in the process.

development research latest technology make most composite materials well as explore new opportunities application such products regular daily activities ANJIE. Modern construction carbon fiber powder fields require constant updates products and technology. ANJIE RD team continuously creating new products offer innovation well as cost efficient solutions cost effective application such materials. Newly developed products often utilized satisfy various application needs clients. Additionally, technical experts help solve problems occur during following project's construction. Online consultation, material support, site visits, testing arrangements so on. Are provided ANJIE.

Since 2004, ANJIE has producing carbon fibre products such ud carbon fabric, fiber rebars, carbon fiber powder grids rods, chopped fiber, etc. materials utilized construction strengthening structural purposes. It well-known its 3k Carbon fiber carbon aramid glasses, carbon aramid hybrid fabric, biaxial fibre fabric silica fiber fabric, more. These the materials extensively used manufacture auto parts, sports, aviation boating. Alongside materials, it dedicated facilities resin products can meet client in demands. From carbon fiber aramid beyond, ANJIE comprehensive range composite materials accommodates range applications across various sectors, such marine, automotive, aerospace, construction, more.

Customer carbon fiber powder products quality assure long-term partnership potential customers, resulting becoming repeat clients. ANJIE supplying composite materials more 20 years. It ISO9001:2015 certification ISO14001 Environmentally, ISO45001 Health and Safety, SGS Factory Evaluation Report, CE Mark many certifications. products made according international standards in line ASTM standards. Products review clients rigorously evaluated respond immediately problems arise products delivered client site. ANJIE's clients around world benefit variety technical assistance. includes experienced team, product samples, solving issues using quality constant customer support.

company among largest composite material producers exporters, specializing mainly carbon fiber powder, carbon fibers, aramid fibres, fiberglass materials. regularly exports world market. It home more 100 patents high-tech equipment working production line. It also dedicated QC team lab test products shipment. latest technology ensures can deliver top quality products consistent manner effectively. It a national company a variety rewards product certifications such ISO, SGS, CE others. When clients require custom reliable products source long-term customer support, ANJIE would a reliable partner achieve success.

Copyright © Haining ANJIE Composite Materials Co., Ltd All Rights Reserved