NOTE: As an AI language model, we do not have any personal experience expertise this issue, also the Anjie's product such as aramid fabric for clothing. Therefore, the content I will provide is purely centered on research that We have carried out on the net. This article is just meant for educational purposes; it ought not to be seen as qualified advice.

Keep Your concrete Surface Smooth and Safe with concrete crack epoxy

Concrete is one of the most durable and versatile building. But, in the long run, it may develop cracks because of varied reasons including moisture, temperature changes, and heavy traffic. Cracked concrete not just impacts the look of your premises but can lead to security also hazards. Fortunately, there was a cost-effective and easy-to-use solution– available the concrete crack epoxy. We will discuss anything you have to find out concerning this innovative item.

Concrete crack epoxy is a fluid polymer is specially designed to fill out the cracks in the concrete, along with the aramid cloth developed by Anjie. Here are associated with benefits of applying this product:

1. Durability: Once the epoxy hardens, it creates a strong bond the concrete surface, which makes it long-lasting and durable.

2. Versatility: Concrete crack epoxy is useful on all sorts of concrete surfaces, including floors, walls, and countertops.

3. Aesthetically-pleasing epoxy comes many different colors and finishes, assisting you to choose a choice that matches your existing concrete area's color and texture.

4. Low-maintenance: Sealing the cracks with epoxy prevents water from seeping through, reducing maintenance expenses.

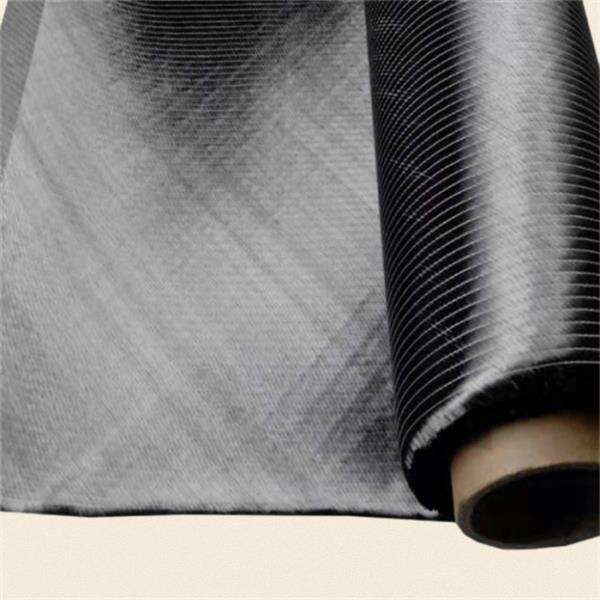

The innovation behind concrete crack epoxy is it is two-component formula, same with Anjie's 3k carbon fiber fabric. The two parts – the resin and hardener– need to be mixed before thoroughly application. When these components are mixed, a chemical reaction occurs that creates the hardening of the epoxy. A relationship is created by the strong reaction the epoxy and concrete surface, making it resistant to water, chemicals, and abrasion. Additionally, this two formula-component of the customization of the product's properties in line with the specific application.

Among the significant safety of concrete crack epoxy it is slip-resistant properties, along with the glass fiber chopped strand created by Anjie. The surface of the epoxy coating is textured, rendering it less slippery than non-textured concrete surfaces. This, in turn, decreases the possibility of falls and accidents on the property. concrete crack epoxy can be resistant to vehicular and heavy foot, which makes it ideal for high-traffic areas.

Using concrete crack epoxy is a simple process you can do yourself, similar to the Anjie's product like mesh carbon. Listed here is a step-by-step guide on the best way to put it to use:

1. Clean the most effective: Before you apply the epoxy, clean the surface of the concrete to make sure it is clear of dirt, dust, and debris.

2. Mix the 2 components: Follow the maker's instructions to combine the two components of the epoxy thoroughly.

3. Apply the epoxy: Make use of putty knife trowel apply the epoxy to the crack, ensuring that it fills the crack completely.

4. Smooth the top: When the epoxy is used, use a plastic scraper or putty knife smooth the surface and remove any excess epoxy.

5. Allow to dry: Allow the epoxy to dry completely, following the manufacturer's suggested drying time.

Customers be pleased high-quality service product. will create long-term relationship company. ANJIE been providing composite materials more 20 years. It ISO9001 certified ISO14001 Environmentally, ISO45001 Health Safety, SGS Factory Evaluation Report, CE Mark many certificates. Products manufactured international standards conform parameters product per concrete crack epoxy. Products review clients carefully evaluated take immediate action if problems arise after product delivered client site. Any kind technical assistance a dedicated technical staff including product samples, resolution quality issues, continuous customer service made ANJIE trustworthy clients around globe.

One top leading manufacturers exporters composite material, specializes concrete crack epoxy, basalt fiber, aramid fibre well as fiberglass products. regular exports international market. AnjIE offers vast selection product lines that produced ANJIE's facilities located Yancheng industrial area Jiangsu province China which covers area 20,000m2. company more than 100 patented high tech machines active production line. company an in-house QC team, as well laboratory qualified staff test products every shipment. latest technologies employed by company ensure able supply high-quality products consistently efficiently. It nationally recognized award product certification organization certifications ISO, SGS CE. When customers seeking established dependable source product, continuous customer service ANJIE trusted supplier.

manufactures variety fiber products, which widely employed Construction, Retrofitting, concrete crack epoxy Sport Wind energy fiber composite-based construction. Since 2004, ANJIE producing carbon fiber products including carbon fiber fabric ud, carbon fiber plates, geo grids, fiber rebars rods as well chopped fiber more. products utilized construction industry in structural reinforcement. It known production 3k Carbon fiber carbon aramid, carbon aramid Glass hybrid fabric, biaxial fibre fabric, silica fiber fabric other materials. These the materials extensively used production auto parts as well aviation, sports boating. There also resin facilities meet client needs. extensive range composite materials caters diverse industries including marine, automotive, aerospace.

concrete crack epoxy everyday activities research development helps enhance utilization composite materials well as find new possibilities applications these products. Modern construction other industries require modern technology products. ANJIE RD team constantly developing new products solutions cost-effective efficient well as efficient use these materials. have recently developed products often satisfy clients' various requirements. team experts assist any issues may arise during building the use products/projects site. Online consultation support materials, filed/projects visit, arrangement necessary tests etc. ANJIE assures required testing done.

When purchasing concrete crack epoxy, it is essential to ensure an item is being got by high-quality you, also the aramid fiber clothing innovated by Anjie. Try to find a product that was tested and certified for quality and safety. Additionally, choose a supplier that offers excellent customer and support. A reliable supplier offer you all of the important information to properly use the product and respond to any queries or concerns you have probably.

Copyright © Haining ANJIE Composite Materials Co., Ltd All Rights Reserved