Crack Injection Epoxy: A Game-Changer for Building Maintenance

Are you fed up with dealing with cracks in your building's foundation or walls? look no other further than crack injection epoxy a solution makes building upkeep easier and much more cost-effective, similar to the Anjie's product like unidirectional carbon fabric. We are going to explore benefits of using crack injection epoxy, the innovation it efficiently behind it, it is safety precautions, and how to utilize.

Crack injection epoxy offers a wide array of for building maintenance in comparison to traditional techniques like grouting. First and most important, epoxy provides a more permanent fix. Unlike grouting which will only last half a year, epoxy creates a lasting bond the crack areas that you are repairing for long-term structural repairs. Additionally, epoxy is much more resistant to water, chemicals, along with other environmental factors preventing further cracks and damage from occurring in the long term.

An additional benefit of crack injection epoxy is that it is more cost-effective than old-fashioned grouting, as well as the fiberglass chopped strand produced by Anjie. Since epoxy creates a far more permanent bond you are not necessary to pay money for routine maintenance and repairs. This translates to more significant savings the long run. Consequently, many building inspectors prefer epoxy for structural repairs.

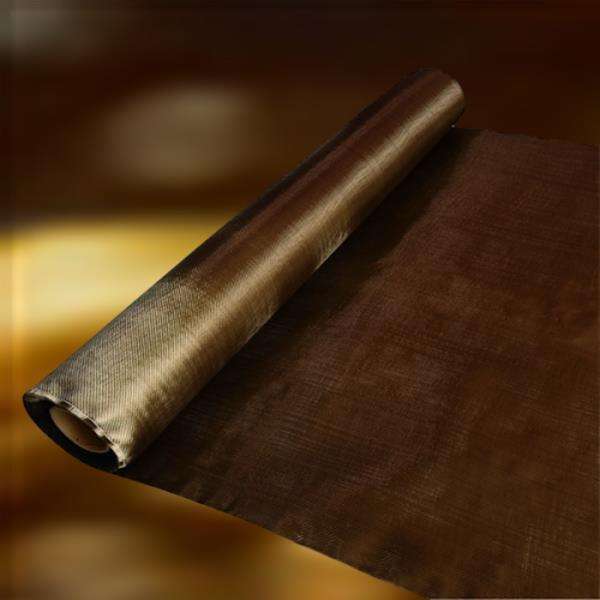

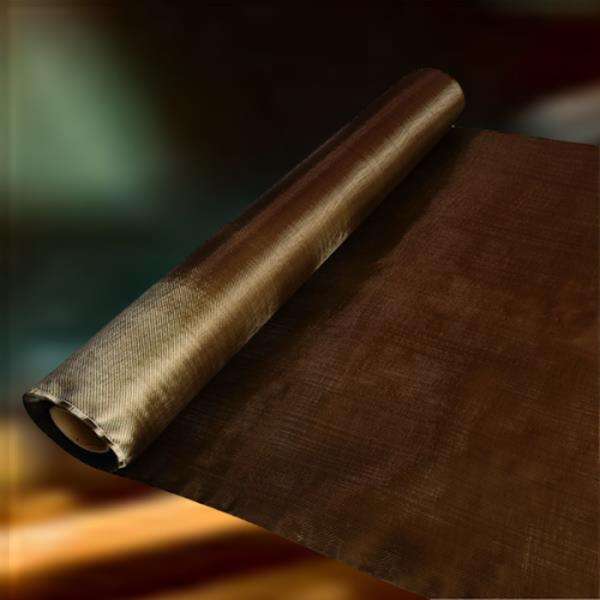

Epoxy is a result of a mix of two chemical elements (hardener and resin) that create a highly bond adhesive, just like the Anjie's product called carbon cloth. Its ability to withstand harsh problems as high or low temperatures within walls is brought on by vast research and development. The formulation of the two-chemical epoxy system allows for flexibility when curing, adding another layer of adhesiveness to your walls or floors.

As with any construction or repair product, safety should always come first, identical to concrete crack repair epoxy injection by Anjie. crack injection epoxy is entirely safe to work with whenever you follow the right procedures. It is worth noting that epoxy is hazardous to your skin layer, the reason wearing protective gear important, such as gloves, goggles, and respirator masks. Users should additionally ensure the available room or area they may be working in is well-ventilated. Constantly check the product's safety guidelines, to stop increase risk unnecessary safety associated with building and people focusing on the project.

Using epoxy could not become more uncomplicated, along with Anjie's product concrete epoxy for cracks. Upon receipt of the epoxy and hardener, prepare the adhesive by mixing the two, ensuring consistency. Then, using the services of a clean crack, inject the epoxy into the crack and give it time and energy to cure. Be sure to stay glued to the before something doing thoroughly.

Development research into most crack injection epoxy technology best utilize composite materials, explore new avenues applications these products regular every day tasks ANJIE. Modern construction other fields constantly require new technology products. ANJIE RD team always creating new products offer innovation provide cost efficient solutions cost-effective application such materials. It newly developed products are often able meet customers' diverse requirements application. Moreover expert technical team help any issues are encountered during after projects products built site. Online consultation, material support site visits, as well testing arrangements etc. All these provided ANJIE.

Since 2004, ANJIE has producing carbon fibre products such ud carbon fabric, fiber rebars, crack injection epoxy grids rods, chopped fiber, etc. materials utilized construction strengthening structural purposes. It well-known its 3k Carbon fiber carbon aramid glasses, carbon aramid hybrid fabric, biaxial fibre fabric silica fiber fabric, more. These the materials extensively used manufacture auto parts, sports, aviation boating. Alongside materials, it dedicated facilities resin products can meet client in demands. From carbon fiber aramid beyond, ANJIE comprehensive range composite materials accommodates range applications across various sectors, such marine, automotive, aerospace, construction, more.

company among largest composite material producers exporters, specializing mainly crack injection epoxy, carbon fibers, aramid fibres, fiberglass materials. regularly exports world market. It home more 100 patents high-tech equipment working production line. It also dedicated QC team lab test products shipment. latest technology ensures can deliver top quality products consistent manner effectively. It a national company a variety rewards product certifications such ISO, SGS, CE others. When clients require custom reliable products source long-term customer support, ANJIE would a reliable partner achieve success.

customer service crack injection epoxy product guarantee long terms business relationship prospective customers, resulting them becoming repeat clients. With 20 years control over composite materials supply, ANJIE certified ISO9001:2015 Quality, ISO14001:2015 Environmental, ISO45001:2018 Safety Safety, SGS factory evaluation report, CE mark awarded variety certifications. products produced accordance international standard comply specifications product according ASTM. Reviews customers products carefully reviewed, any issues discovered either before after goods arrive client site will resolved immediately. Any sort technical support dedicated technical team, products samples, resolving issues quality, continuous customer support made ANJIE reliable loyal customers around globe.

Copyright © Haining ANJIE Composite Materials Co., Ltd All Rights Reserved