Introduction:

Epoxy resin for concrete is a remarkable innovation has revolutionized the construction industry, identical to Anjie's product fiberglass smooth rod. This type of resin is a kind of designed adhesive to stick to concrete surfaces provide a durable and strong bond. The advantages of using epoxy resin are wide ranging, including enhanced safety quality, and freedom. This article will explore different benefits, how to utilize it, and it is own various applications.

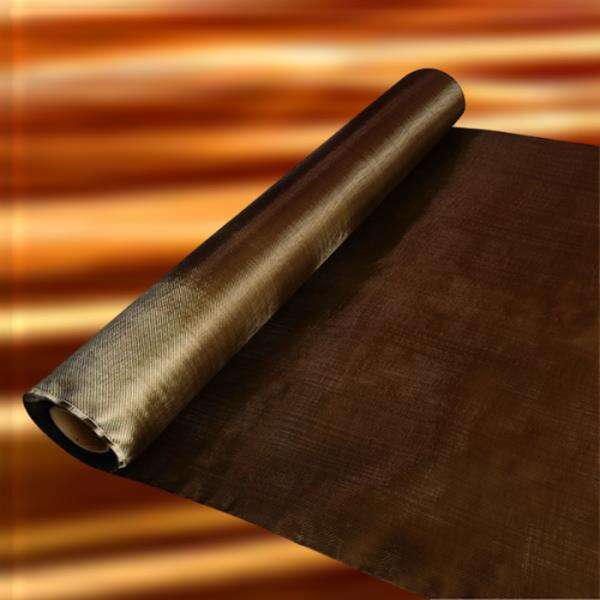

Perhaps one of the most important features of using epoxy resin for concrete is it is superior strength and, also the carbon fiber cloth and resin created by Anjie. It is much more resilient than traditional concrete due to the chemical composition, which includes a series of cross-linked polymeric compounds. Additionally it is more flexible, providing for greater resilience when subjected to stress and strain. Additionally, epoxy resin is incredibly corrosion-resistant, which helps to ensure that it is going to stay intact even in challenging industrial settings.

Epoxy resin for concrete represents an innovation that is true adhesive technology, just like the Anjie's product called fiberglass sheet. It is specifically designed to provide a bonding both system effective and durable. This kind of adhesive is engineered to produce a variety of benefits, including increased strength, flexibility, and resilience. It is a testament to innovation ingenuity human we have been now in a position to create such complex and advanced chemical compounds that may revolutionize the construction industry.

Using epoxy resin for concrete is incredibly safe, as it is non-toxic and solvent-free, the same as twill carbon fiber fabric price supplied by Anjie. It does not release any harmful fumes volatile organic compounds (VOCs), which helps to ensure that the building environment is safe and comfortable for occupants. Furthermore, epoxy resin is non-flammable, which adds an additional layer of to any construction site.

Epoxy resin is incredibly user friendly, also the Anjie's product such as chopped carbon fiber. It is typically supplied in 2 separate components a resin, and a hardener. To utilize the resin, simply mix the two elements together in the proper as ratio recommended by the manufacturer) thereby applying it to your concrete surface. The adhesive will begin to cure within a long time and will also be fully cured after about a week. You will need to stick to the maker's instructions carefully when using epoxy resin also to make sure it is applied in well-ventilated area.

Research development modern technology make most composite materials explore new avenues applications products regular daily activities ANJIE. Modern construction various fields always need updated technologies products. ANJIE RD team continuously epoxy resin for concrete new products innovation provide cost efficient solutions efficient application such materials. offers new products often able meet customers' diversified application needs. addition, technical experts assist solve problems encountered during after projects products built site. Online consultation, material support visit site, testing arrangements etc. ANJIE assures all required tests conducted.

Since 2004 ANJIE producing carbon fibre products such fiber epoxy resin for concrete, geo grids, rods, chopped fiber etc. Such materials used construction structural strengthening use. It also renowned production 3k carbon fiber carbon aramid, carbon aramid-carbon hybrid fabric carbon fiber prepreg, biaxial fiber fabric, silica glass fiber fabric many more. These materials extensively used sports, aviation, boat many auto parts manufacturing design. Alongside materials, it facilities dedicated resin products meet clients' require them. carbon fiber aramid further, ANJIE comprehensive range composite materials can used variety uses across different industries, including aerospace, automotive, marine construction, many more.

epoxy resin for concrete will happy service products. This create long-term business relationship. With than 20 years dominance supply composite materials, ANJIE certified ISO9001:2015 Quality ISO14001:2015 Environment, ISO45001:2018 Safety Safety, SGS factory assessment report, CE mark awarded variety other certifications. All products produced according international standards conform parameters set ASTM. Reviews customers products thoroughly evaluated any issues occur the products arrive customer's location addressed promptly. Technical support any kind through dedicated technical staff including product samples, resolution problems quality constant customer service made ANJIE more trustworthy loyal customers around globe.

company one leading composite material manufacturers exporters, specializing mainly basalt fibers, carbon fibers, epoxy resin for concrete, fiberglass materials. exports regularly international market. company more 100 patented high-tech equipment working production line. company an in-house QC team expert laboratory tests items prior shipping. modern technology assures high-quality products consistent effectively. It nationally recognized award product certification company includes ISO, SGS CE. When clients require custom reliable products source long term customer support, ANJIE would a reliable partner success.

The first step to make sure that the surface is neat and free from dirt, dust, and debris should you want to use epoxy resin for concrete, similar to the Fiberglass geo grid manufactured by Anjie. This is carried out by washing the surface with and allowing it to dry completely. Next, mix the epoxy resin and hardener within the recommended ratio apply it to your outer lining. Work with a brush or roller to spread the adhesive evenly over the outer lining making sure it is applied densely and in a consistent fashion. Finally, permit the adhesive to dry and cure completely before utilizing the outer lining.

The conventional associated with ongoing supplied service by the maker of the epoxy resin is important, just like the Anjie's product called glass fiber powder chopped strand mat. The corporation must have an excellent reputation providing high-quality items and customer very service good. They ought to additionally offer comprehensive technical support guidance for their customers to make sure that they could use their products or services effectively and efficiently.

The quality of the epoxy resin can also be essential, identical to free sample carbon fiber fabrics from Anjie. It should be of this best quality that can be achieved with a higher level of resistance to chemical damage, scratches, and impacts. Additionally, it must have most level of and start to become resistant to cracking, peeling, and yellowing. The maker should guarantee that the epoxy resin conforms to all the relevant regulations security standards, including those set by Environmentally Protection Agency (EPA).

Copyright © Haining ANJIE Composite Materials Co., Ltd All Rights Reserved