Making Stronger Buildings with Fiberglass Rebar Making Machine

Advantages of Using fiberglass rebar

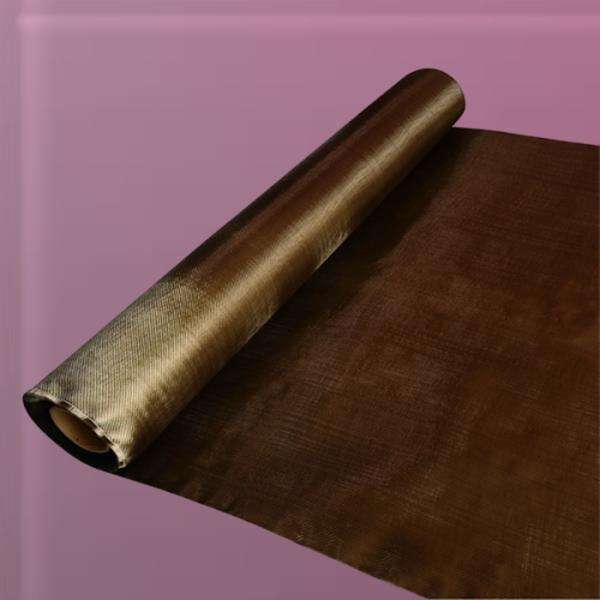

Fiberglass rebar is a type of reinforcing made bar of glass fiber. It is a lightweight and durable alternative steel rebar.traditional fiberglass rebar Has many advantages steel rebar. First, it's highly resistant to corrosion and does not rust like steel. This makes it perfect for use in concrete exposed structures to harsh weather. Second, fiberglass rebar and also the anjie sand coated fiberglass rebar are stronger than steel rebar. A strength is had by tensile it is 3 x greater than that of steel. This means that it could resist greater stress and pressure than steel rebar. This makes it perfect for use in buildings, roads, bridges, and other infrastructure.

The anjie fiberglass rebar making machine is a miracle of innovation and engineering. It is designed a machine to create strong and durable fiberglass rebar quickly and efficiently. The machine utilizes a process called pultrusion. The fibers into the desired rebar shape in this process, glass fibers are pulled through a resin bath and then through a die that shapes.

The pultrusion procedure is a very efficient method of. It allows for the manufacturing of rebar in large quantities, which helps to bring the cost down of the material. The machine is also relatively simple to operate, which means that workers don't need specialized training operate it.

Safety is just a top priority it comes to building structures. fiberglass rebar is a safe alternative to steel rebar. It does not conduct electricity, rendering it safe to use in exposed structures to electrical current. It normally non-magnetic, which makes it suitable for use in MRI rooms and other areas where magnetic areas present.

Additionally, fiberglass rebar and also the anjie basalt rebar is lightweight and simple to manage. This reduces the risk of problems for workers who are handling the material. The fiberglass rebar making machine is also designed with safety in mind. It has guards and safety features that prevent accidents and injuries during procedure.

Using anjie fiberglass rebar making machine is relatively effortless. The machine is made to perform all of the essential actions the pultrusion procedure automatically. The operator merely needs to load the machine with the appropriate materials set the parameters for the desired rebar size and shape. Once the machine is initiated, it shall pull the cup fibers through the resin bath plus the die, shaping them into the desired rebar shape. The rebar is then cut to the desired length and packaged for shipping. The entire process done quickly and efficiently, allowing for the production of large quantities of fiberglass rebar in a short period of time.

The quality of fiberglass rebar is of this utmost importance same with anjie Carbon fiber rebar rod. The fiberglass rebar making machine of produces rebar the greatest quality. The machine is designed to ensure that the glass materials are fully impregnated with the resin, which creates a more bond powerful than steel. Additionally, the pultrusion process ensures that the rebar is uniform in size and shape. This means that there are no weak spots defects in the rebar, which can compromise the strength of the structure. The quality of the rebar is also tested before it is shipped to ensure that it fulfills all necessary standards and specifications.

manufactures variety fiber products, which widely employed Construction, Retrofitting, fiberglass rebar making machine Sport Wind energy fiber composite-based construction. Since 2004, ANJIE producing carbon fiber products including carbon fiber fabric ud, carbon fiber plates, geo grids, fiber rebars rods as well chopped fiber more. products utilized construction industry in structural reinforcement. It known production 3k Carbon fiber carbon aramid, carbon aramid Glass hybrid fabric, biaxial fibre fabric, silica fiber fabric other materials. These the materials extensively used production auto parts as well aviation, sports boating. There also resin facilities meet client needs. extensive range composite materials caters diverse industries including marine, automotive, aerospace.

ANJIE's daily activities include research development improve use composite materials discover potential applications new fiberglass rebar making machine these materials. Modern construction other fields always require modern technology products. ANJIE's RD team always exploring new product innovations as well cost efficient solutions efficient application materials. Products are newly developed usually utilized satisfy various demands clients. Moreover expert technical team help any issues arise during after products/projects construction site. Active online consultancy, materials support, visits projects/files, arrangements needed testing etc. ensured ANJIE.

One thefiberglass rebar making machine leading producers exporters composite materials specializes carbon fiber, basalt fiber, aramid fiber fiberglass products. They regular exports international marketAnjie a wide range products manufactured ANJIE facilities the Yancheng industrial area Jiangsu province China with industrial area 20000 square meters. It over 100 high-tech machines active production line. It dedicated QC team labs test products each shipment. modern technologies used company ensure supply quality products consistently effectively. It holds range national rewards products certification including ISO, SGS, CE others. When clients require custom reliable sources products long-term client support, ANJIE would a reliable partner success.

customers will satisfied with service products. This lead long-term business relationship. With 20 years supremacy supply composite materials, fiberglass rebar making machine certified ISO9001:2015 Quality, ISO14001:2015 Environmental, ISO 45001:2018 Health Safety, SGS factory evaluation report, CE mark awarded numerous certificates. products produced accordance international standard comply products parameter according ASTM. Client reviews carefully evaluated make immediate changes problems occur after goods received clients site. clients ANJIE around globe received range technical assistance, including experienced team, product examples, solving problems quality, continuous customer support.

Fiberglass rebar from anjie can be used in a type of applications. It is perfect for use in exposed structures to harsh weather, such as bridges, water treatment plants, and coastal structures. It's also suitable for use in exposed structures to chemicals, such as industrial plants and wastewater treatment facilities. Additionally, fiberglass rebar is suitable for use in subjected structures to electromagnetic fields such as MRI rooms and electrical power. Its non-magnetic properties make it an ideal material used in these types of structures.

Copyright © Haining ANJIE Composite Materials Co., Ltd All Rights Reserved