Injectable Concrete Epoxy: Transforming the Way We Repair Damaged Concrete

Introduction

You discover how unsightly and in addition hazardous it could be if you have ever came across a cracked sidewalk, as well as the Anjie's carbon tow 12k. Happily, there was a remedy which includes become a game-changer in the market of concrete repair: Injectable concrete epoxy. We are going to explore this innovative product advantages, safety, and quality, alongside how to utilize it along with it is feasible applications.

Injectable concrete epoxy has numerous benefits traditional concrete repair methods, similar to the carbon fibre effect laminate from Anjie. For beginners, it is stronger and a lot more long-lasting. Also, it will probably work as a barrier to water along with other external elements making the concrete more resistant to erosion and harm. Additionally, injectable concrete epoxy can be employed in a number of applications, both small and large, giving home owners more flexibility.

Injectable concrete epoxy is a major innovation the field of concrete repair, just like the Anjie's product called concrete anchoring epoxy. It has changed the real way we perceive repairing and maintaining concrete. Unlike traditional concrete repair looking techniques for removing and replacing the entire damaged concrete allows for repairs in little and targeted areas only, saving time, money, and work.

Safety is obviously a top problem any product, and injectable concrete epoxy is no exception, the same as basalt composite supplied by Anjie. Fortunately, this system is safe to utilize, non-toxic, and environmentally friendly. In addition it meets all the necessary industry and standards. In terms of use, injectable concrete epoxy is an easy task apply. All you have to do is mix the epoxy, place it into a specialized applicator and inject it in to the affected concrete.

Using injectable concrete epoxy is simple, as well as can get up to speed, same with Anjie's china 3k twill carbon cloth. The first step to clean the damaged concrete surface then mix the epoxy based regarding the instructions provided. Next, fill the epoxy to the applicator gun and dispense it in to the affected area. Finally, smooth it out and allow it to cure. And that is it. You will have a sturdy and reliable repair will last for years.

Customers be pleased quality service products. can lead long-term relationships customers. over 20 years dominance composite materials supply, ANJIE certified ISO9001:2015 Quality injectable concrete epoxy:2015 Environment, ISO 45001:2018 Safety Safety, SGS factory evaluation report, CE mark awarded numerous other certificates. Products made accordance international standards conform products parameter according ASTM. reviews customers products thoroughly evaluated make immediate changes problems occur products delivered client site. Any type technical support dedicated team technical experts product samples, well as resolving problems quality constant customer support made ANJIE trustworthy valuable clients across globe.

One theinjectable concrete epoxy leading producers exporters composite materials specializes carbon fiber, basalt fiber, aramid fiber fiberglass products. They regular exports international marketAnjie a wide range products manufactured ANJIE facilities the Yancheng industrial area Jiangsu province China with industrial area 20000 square meters. It over 100 high-tech machines active production line. It dedicated QC team labs test products each shipment. modern technologies used company ensure supply quality products consistently effectively. It holds range national rewards products certification including ISO, SGS, CE others. When clients require custom reliable sources products long-term client support, ANJIE would a reliable partner success.

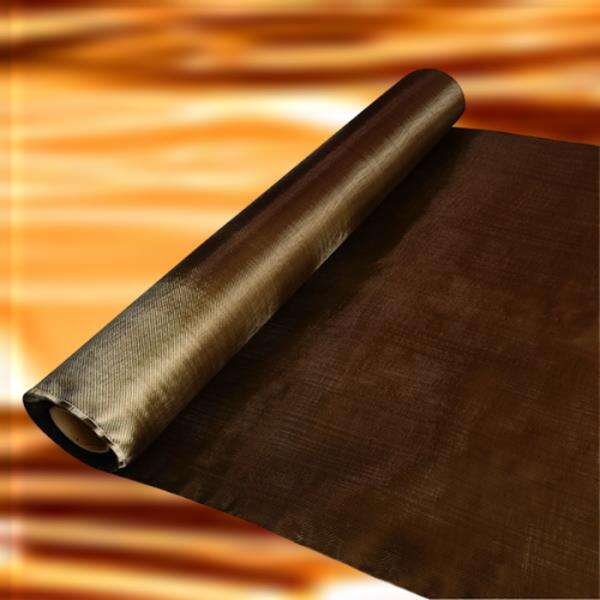

injectable concrete epoxy various fiber products, which extensively utilized Construction, Retrofitting, Automotive sports, Wind energy, many other fiber composite based construction. Since 2004, ANJIE producing carbon fiber products, including carbon fiber fabric ud carbon fiber plates geo grids, fiber rebar rod as well chopped fiber so on. products utilized construction structural reinforcement. It also renowned production 3k carbon fiber carbon aramid glass hybrid fabric carbon fiber prepreg, biaxial fiber fabric, silica fiber fabric numerous others. materials widely used sports, aviation boats, other auto parts manufacturing modeling. Along materials, it dedicated facilities resin products support clients demands. From carbon fiber aramid further, ANJIE comprehensive range composite materials caters diverse applications across various industries, including aerospace, automotive, marine, construction, more.

development research latest technologies maximize use composite materials seek new avenues applications such materials common everyday activities ANJIE. Modern construction various fields require constant updates technology products. ANJIE RD team continuously working new product innovation solutions that cost-effective efficient well as cost-effective application materials. offers new products usually meet clients' diverse requirements application. team experts able assist any difficulties which arise during building use products/projects on site. live online consultation assistance materials, injectable concrete epoxy visit, arrangement needed testing etc. ANJIE assures all required testing done.

Copyright © Haining ANJIE Composite Materials Co., Ltd All Rights Reserved