- Overview

- Parameter

- Features

- Inquiry

- Related Products

| Place of Origin: | China |

| Brand Name: | ANJIE/NCE |

| Model Number: | ERCFF |

| Certification: | *** |

| Minimum Order Quantity: | 100 kg |

| Price: | *** |

| Packaging Details: | *** |

| Delivery Time: | 5-15 days |

| Payment Terms: | Bank TT/LC/Paypal/Credit Card/Local RMB payment |

| Supply Ability: | 1000kg/week |

Description:

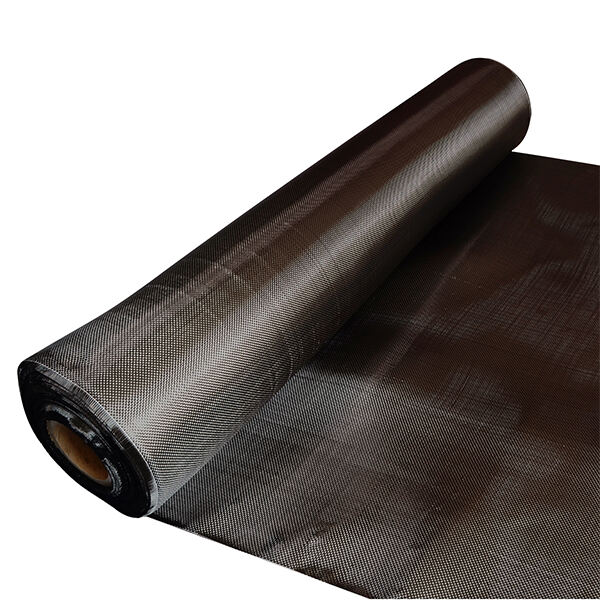

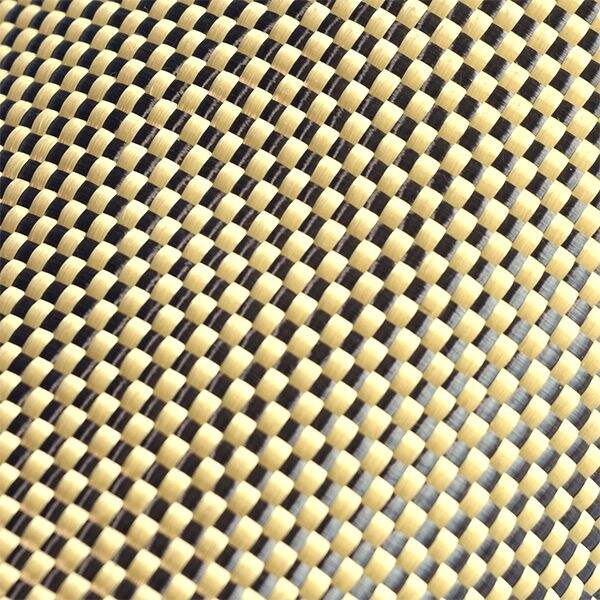

Epoxy resin is commonly used as both a matrix material and adhesive for carbon fabric composites. It serves a dual purpose by providing the bonding strength between layers of carbon fabric as well as acting as a matrix to encapsulate and reinforce the carbon fibers.

The high strength, excellent bonding properties, and versatility of epoxy resin make it a preferred choice for adhesive applications with carbon fabric. Its ability to provide strong adhesion, durability, and chemical resistance contributes to the overall performance and longevity of carbon fabric composite structures.

Applications:

Uses as structural adhesive to use with fiber wrap/fabric for reinforcement, strengthening bridge, wall and any other structural retrofitting.

Competitive Advantage:

Customized Production

Project based solutions

Project technical support

Experienced stuff

Operational Efficiency/shorter lead time

Best factory price

Sample services

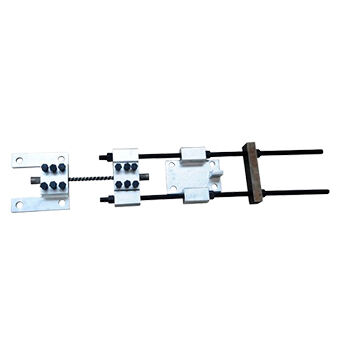

| Appearance | Component A: transparent viscous liquid | Operable time (min)(25℃): | >30 |

| Component B: brown viscous liquid | Finger touch dry time (20 ℃, h) | 1~2 | |

| Bonding strength: | C60 concrete damage | Mixture ratio(by weight) | 2:1 |

| Viscosity of mixtures: | 4000-6000 Pa.s | Curing material density | 1.10±0.10g/cm3 |

| STEEL–STEEL BONDING strength | ≥14 Mpa | PULLING ADHESION STRENGTH WITH CONCRETE | ≥ 2.5 Mpa |

| TENSILE STRENGTH | ≥ 45 MPa | TENSILE ELASTIC MODULUS | ≥ 2500 Mpa |

| ELONGATION | ≥ 2.5 % | BENDING STRENGTH | ≥ 70 Mpa |

| COMPRESSIVE STRENGTH | ≥ 77 Mpa |

EN

EN

AR

AR

NL

NL

FR

FR

HI

HI

IT

IT

KO

KO

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

VI

VI

TH

TH

TR

TR

AF

AF

MS

MS

UR

UR

NE

NE

TA

TA

MY

MY

UZ

UZ

KY

KY