Injection de Fissures de Béton - Solution Innovante pour des Réparations de Haute Qualité

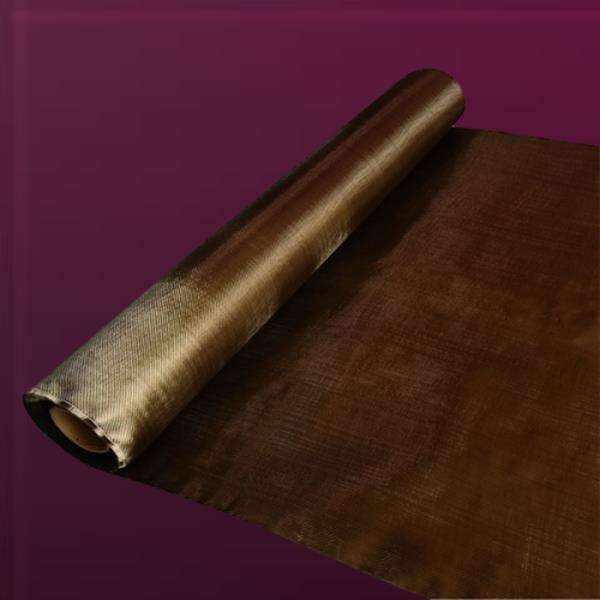

Avez-vous déjà vu des fissures dans le béton ? Les fissures apparaissent parfois lorsque le béton vieillit ou lorsqu'un objet lourd tombe dessus, ainsi que chez Anjie's Feuille en fibre de carbone préimprégnée . Mais ne vous inquiétez pas. Il existe un remède qui peut réparer ces fissures et rendre le béton comme neuf. Cela s'appelle l'injection de fissures de béton. C'est spécial parce qu'il utilise un liquide pour remplir les fissures au lieu de mettre du nouveau béton sur l'ancien. Cela signifie que vous n'avez pas à attendre des jours pour que les réparations sèchent avant de réutiliser le béton.

Il existe de nombreux avantages à utiliser l'injection de fissures en béton pour les réparations. Premièrement, c'est une solution rapide et économique. Les réparations traditionnelles peuvent prendre des jours ou des semaines pour être réalisées, et elles nécessitent également beaucoup de main-d'œuvre et de matériaux. Mais avec l'injection de fissures, les réparations sont possibles rapidement, et vous devrez dépenser moins d'argent pour les matériaux et la main-d'œuvre.

De plus, l'injection de fissures crée un lien solide qui dure longtemps. Le liquide remplit toute la fissure et crée un joint étanche à l'eau. Cela signifie que les réparations peuvent durer de nombreuses années sans nécessiter d'entretien supplémentaire.

Enfin, l'injection de fissures est une solution sûre et respectueuse de l'environnement, ainsi que celle feuille en kevlar fabriquée par Anjie. Le liquide utilisé est non toxique et ne détériore pas l'environnement. De plus, comme il n'est pas nécessaire d'enlever ou de remplacer le vieux béton, il y a moins de déchets créés, ce qui est meilleur pour l'environnement.

L'injection de fissures dans le béton est une solution innovante pour réparer les fissures dans le béton, de la même manière que celle d'Anjie. tissu carbone aramid au lieu d'utiliser des techniques traditionnelles comme le burin ou le remplacement, un liquide est utilisé pour remplacer l'ancien béton et combler les fissures par injection. Ce liquide est spécialement conçu pour s'écouler dans les plus petites fissures et créer une liaison puissante et étanche à l'eau.

L'injection de fissures dans le béton peut être utilisée avec succès pour réparer des fissures dans de nombreuses structures différentes, y compris les bâtiments, les ponts et les routes, ainsi que celle feuille de fibre de verre produite par Anjie. Elle fonctionne mieux sur des fissures de moins de 1/4 de pouce de large. Si les fissures sont plus larges, d'autres méthodes de réparation peuvent être nécessaires.

Le processus complet d'utilisation de l'injection de fissures dans le béton n'est pas difficile, tout comme le produit d'Anjie appelé bande de carbone tout d'abord, la fissure est préparée et lavée afin que votre liquide adhère correctement. Ensuite, le liquide est injecté dans la fissure à l'aide d'équipements spéciaux. Le liquide va s'écouler dans la fissure et la remplir complètement, formant un lien solide. Enfin, tout excès de liquide est essuyé et la surface est lissée pour correspondre au béton environnant.

Les activités d'injection de fissures dans le béton d'ANJIE comprennent la recherche, le développement, l'amélioration de l'utilisation des matériaux composites et l'exploration de nouvelles opportunités d'applications de ces matériaux. La construction moderne et d'autres domaines nécessitent toujours des technologies et produits mis à jour. L'équipe R&D d'ANJIE explore continuellement de nouvelles innovations de produits ainsi que des solutions efficaces en termes de coûts et d'application de tels matériaux. L'entreprise a récemment développé des produits souvent capables de répondre aux diverses exigences des clients. Une équipe d'experts assiste sur toute question pouvant surgir lors de la conception et de la mise en œuvre des projets sur site. Des consultations en ligne, un soutien en matière de matériaux, des visites sur site, des dispositions pour les tests, etc., sont fournis par ANJIE.

injection de fissures dans le béton, divers produits en fibres, largement utilisés dans la construction, la rénovation, l'automobile sportive, l'énergie éolienne et de nombreuses autres constructions basées sur des composites de fibres. Depuis 2004, ANJIE produit des produits en fibre de carbone, y compris des tissus en fibre de carbone ud, des plaques en fibre de carbone, des géoréseaux, des barres de renfort en fibre ainsi que des fibres hachées et bien d'autres. Les produits sont utilisés pour le renforcement structurel en construction. Elle est également réputée pour la production de tissu hybride en fibre de carbone, aramide et verre, préimprégné en fibre de carbone, tissu en fibre biaxiale, tissu en fibre de silice et de nombreux autres. Ces matériaux sont largement utilisés dans les sports, l'aéronautique, les bateaux et d'autres pièces automobiles pour la fabrication et la modélisation. En plus des matériaux, elle dispose d'installations dédiées à des produits résineux pour répondre aux besoins des clients. Du carbone aramidique et au-delà, ANJIE propose une gamme complète de matériaux composites adaptés à diverses applications dans divers secteurs, y compris l'aérospatial, l'automobile, le maritime, la construction et bien d'autres.

Un des principaux fabricants et exportateurs de matériaux composites, spécialisés dans l'injection de fissures en béton, les fibres de basalte, les fibres d'aramide ainsi que les produits en fibre de verre. Des expéditions régulières sont effectuées vers le marché international. AnjIE propose une large gamme de lignes de produits qui sont produites dans les installations d'ANJIE situées dans la zone industrielle de Yancheng, province du Jiangsu, en Chine, couvrant une superficie de 20 000 m². L'entreprise possède plus de 100 machines à haute technologie brevetées et une ligne de production active. L'entreprise dispose également d'une équipe QC interne, ainsi qu'un laboratoire avec un personnel qualifié pour tester les produits avant chaque envoi. Les dernières technologies utilisées par l'entreprise garantissent la capacité de fournir des produits de haute qualité de manière constante et efficace. Elle est reconnue nationalement et a obtenu des certifications d'organismes de certification de produits tels que ISO, SGS et CE. Lorsque les clients recherchent une source établie et fiable de produits, le service client continu d'ANJIE en fait un fournisseur de confiance.

les clients seront satisfaits par des produits et services de qualité. Cela peut conduire à une relation commerciale durable. ANJIE fournit des matériaux composites depuis plus de 20 ans. Il est certifié pour l'injection de fissures dans le béton selon ISO14001 Environnement, ISO45001 Santé et Sécurité, Rapport d'Évaluation d'Usine SGS, Marque CE ainsi que de nombreux autres certificats. Les produits sont fabriqués selon des normes internationales et respectent les paramètres définis par ASTM. Les produits sont examinés attentivement par les clients, et toute action immédiate est prise si des problèmes surviennent pendant ou après la livraison du produit sur le site du client. Toute sorte d'assistance technique est offerte par un personnel technique dédié, y compris des échantillons de produits, la résolution des problèmes liés à la qualité, et un soutien continu aux clients, ce qui rend ANJIE fiable et précieux pour ses clients du monde entier.

Si vous souhaitez réparer des fissures dans le béton, il est nécessaire de choisir une organisation réputée qui offre des services de haute qualité, comme ceux de carbone en alvéoles produit par Anjie. Cherchez une entreprise expérimentée en injection de fissures avec un historique prouvé de réussite. Elle doit également offrir des garanties sur le travail effectué pour vous assurer que les réparations dureront.

Il est crucial de sélectionner une solution de haute qualité qui durera de nombreuses années, comme les produits d'Anjie. camouflage en fibre de carbone l'injection de fissures dans le béton est une solution durable et de longue durée, soutenue par une garantie en ce qui concerne les réparations de béton. En choisissant l'injection de fissures, vous pouvez être confiant que votre béton aura belle allure et restera solide pendant très longtemps.

Droits d'auteur © Haining ANJIE Composite Materials Co., Ltd Tous droits réservés