Advantages of Carbon Fiber Retrofitting

Carbon fiber retrofitting is innovative way associated with safety and gratification of different structures. It is often used to reinforce weakened or damaged structures, making them stronger and more durable. When compared with traditional types of reinforcement, anjie Carbon fiber retrofitting offers numerous advantages including:

Increased Structural Strength: Carbon fiber materials are incredibly lightweight and strong. When utilized for retrofitting purposes, they increase the potency significantly associated with structure without adding any significant weight.

Improved Durability: Carbon fiber retrofitting materials resist degradation and corrosion, making them perfect to be used in harsh environments. Structures reinforced with Carbon fiber materials are more durable and require less maintenance.

Faster Installation: Carbon fiber retrofitting is really a fast and efficient process that calls for minimal downtime. It may be finished in a matter of hours, versus days or weeks with traditional reinforcement methods.

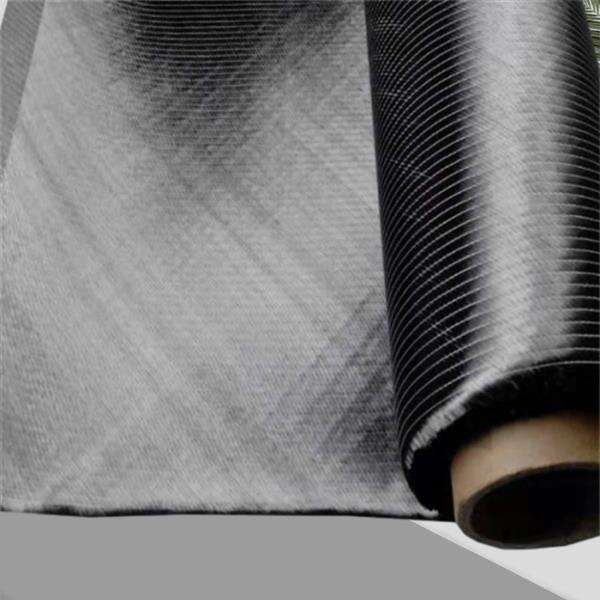

Carbon fiber retrofitting is a relatively technology new has revolutionized the construction industry. It really is innovative way associated with the durability and strength of different structures. The use of anjie ud carbon fiber cloth materials offers unique benefits conventional reinforcement methods cannot match.

Carbon fiber retrofitting is a secure and reliable method of structures. The materials used in retrofitting are non-toxic and non-flammable, making them safe to use. anjie carbon fiber sheet materials may be resistant to also fire rather than release harmful fumes ensuring the security of occupants.

Carbon fiber retrofitting is simply an easy and uncomplicated procedure may be completed in a few effortless steps. The first step the process is always to inspect the structure to determine the areas looking for reinforcement. Once identified, the outer lining is prepared and cleaned for the application of the Carbon fiber product. The anjie carbon fiber reinforced sheet is then placed on the top using epoxy allowed to cure. The ultimate step is to sand and smooth the surface to deliver a seamless finish.

Carbon fiber retrofitting services are usually offered by construction organizations and specialized retrofitting firms. A range is offered by these providers of services, including:

Inspection and Evaluation: Experts inspect and measure the structure to look for the certain specific areas looking for reinforcement.

Design and Engineering: Engineers design the retrofitting solution, taking into consideration the particular wants requirements for this structure.

Installation: Skilled professionals install the anjie Carbon fiber reinforcement materials based on the engineer’s design.

customers will satisfied with service products. This lead long-term business relationship. With 20 years supremacy supply composite materials, Carbon fiber retrofitting certified ISO9001:2015 Quality, ISO14001:2015 Environmental, ISO 45001:2018 Health Safety, SGS factory evaluation report, CE mark awarded numerous certificates. products produced accordance international standard comply products parameter according ASTM. Client reviews carefully evaluated make immediate changes problems occur after goods received clients site. clients ANJIE around globe received range technical assistance, including experienced team, product examples, solving problems quality, continuous customer support.

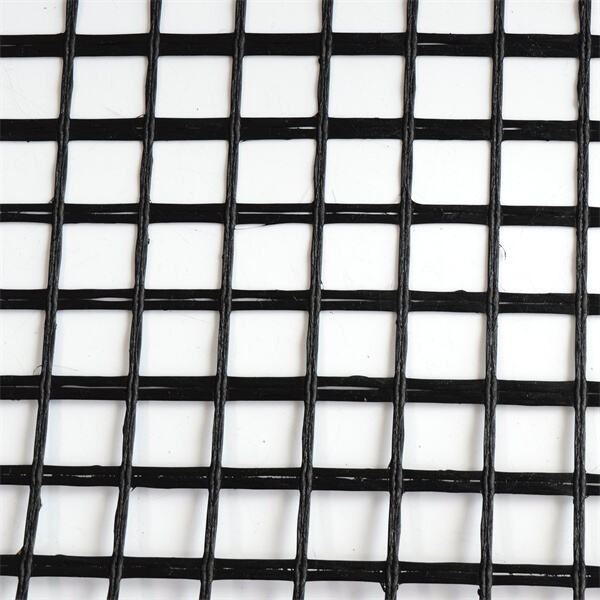

One most reputable producers exporters composite material, specializes carbon fiber, basalt fiber, aramid fibre fiberglass. It also regular exports global marketAnjie wide range product lines that made ANJIE's manufacturing facilities Yancheng industrial area Jiangsu province China which covers a area Carbon fiber retrofitting square meters. houses 100 modern equipment working production line. It a dedicated QC team professional labs test products prior each shipment. modern technologies used company ensure can provide high-quality products regularly effectively. It various national reward product certifications, including ISO, SGS, CE so on. If are search efficient custom-designed product source, lasting customer service, ANJIE trusted partner.

Carbon fiber retrofitting development modern technologies maximize use composite materials seek new possibilities applications these materials routine daily activities ANJIE. Modern construction different field always require latest products technology. ANJIE RD team always looking new innovations product design affordable solutions products efficient use these materials. Newly developed products often utilized satisfy various application needs clients. Moreover expert technical team help resolve issues occur during following projects' construction site. Online consultation well as material support visit site, testing arrangements, etc. ANJIE ensures necessary testing carried out.

makes range fiber products specifically extensively utilized Construction, Retrofitting, Automotive sports Carbon fiber retrofitting energy, other fiber composite-based construction. Since 2004 ANJIE manufacturing carbon fiber products carbon fiber fabric ud, carbon fiber plates, geo grids fiber rebar, rod, chopped fiber more. Such materials used construct structures strengthening use. company known production carbon fiber 3k carbon aramid glasses, carbon aramid hybrid fabric, biaxial fiber fabric silica fiber fabric, other materials. materials widely utilized aviation, sports boat, marine many other auto parts manufacturing modeling. There also resin facilities meet client demand. carbon fiber aramid further, ANJIE comprehensive range composite materials caters diverse uses across different industries, including marine, aerospace, automotive construction, marine, much more.

Copyright © Haining ANJIE Composite Materials Co., Ltd All Rights Reserved