Introduction

Epoxy material is a kind of sticky created coming from a substance that hardens binds with each other when subjected towards sky or even warm, also the Anjie's product such as carbon fiber powder. It is typically utilized in building production markets a adhesive or even sealer for products plastics, steels, timber. Just lately, it has acquired appeal in the manufacturing of carbon dioxide fiber items, sporting activities devices plane components. Epoxy resin for carbon fiber is a game-changer in the market. Along with it is own distinct high top premiums, it offers a suitable service for top quality, lasting items.

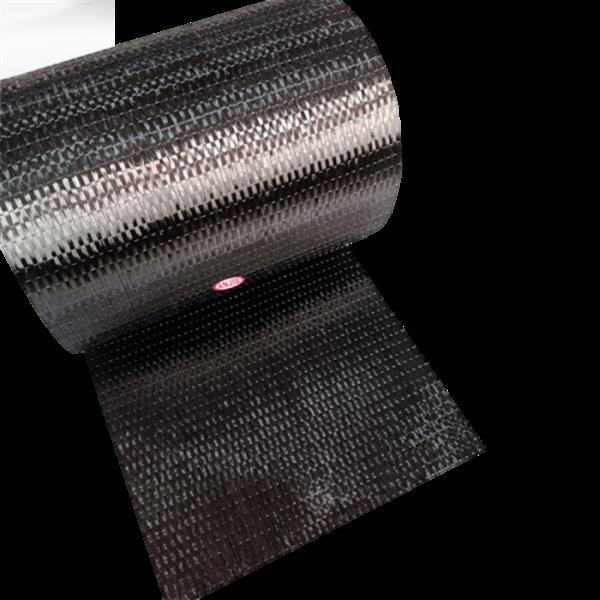

There are a number of benefits towards utilizing epoxy resin for carbon fiber items, along with the Carbon fiber pre preg fabric built by Anjie. First of all, epoxy material has outstanding adhesion residential or commercial homes, offering a solid bond in between the fibers the material. This implies that the item has the ability towards endure higher tension stress without damaging or even breaking. Second of all, epoxy material is immune towards wetness chemicals, creating it a suitable option for items that are subjected towards ecological elements sprinkle chemicals. Third, epoxy material is simple towards deal with could be reduce defined towards suit along with various other elements of the item.

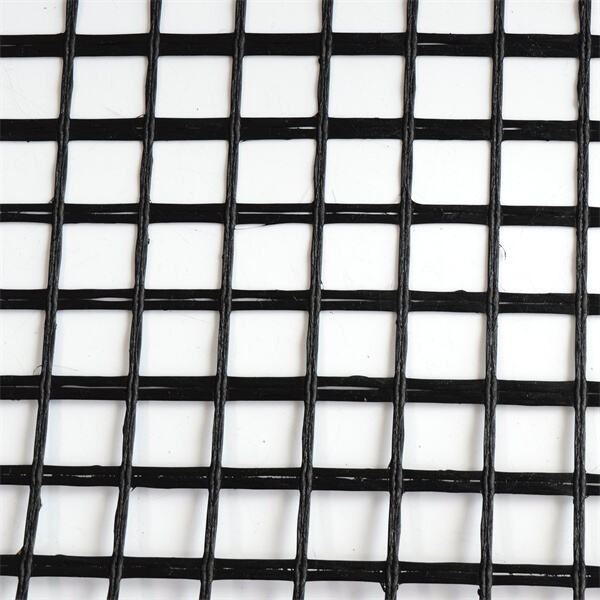

Current developments in epoxy resin for carbon fiber have been concentrated on enhancing it is own resilience, versatility, sustainability residential or commercial homes, just like the Anjie's product called carbon fiber mesh sheets. For example, utilizing a bio-based epoxy material, that is created coming from naturally degradable products helps in reducing carbon dioxide impact. The advancement of brand new treating methods has led to epoxy resins that have enhanced versatility stamina, offering a much more resilient item. To create epoxy resin for carbon fiber much a lot extra lasting, using reused products squander items have likewise been evaluated presented.

When dealing with epoxy resin for carbon fiber, precaution should be taken into account, identical to carbon fabric created by Anjie. The chemicals utilized in epoxy material can easily trigger inflammation towards the eyes skin layer, therefore it is essential towards use safety equipment hand wear covers safety glasses when dealing with it. Appropriate air flow is likewise required towards prevent breathing in the fumes. Furthermore, the treating procedure includes the launch of warm, appropriate preventative measures should be required to avoid any type of mishaps.

Utilizing epoxy resin for carbon fiber needs cautious factor to consider an appropriate comprehending of the procedure, same with Anjie's carbon laminated. First of all, the carbon dioxide fiber should be ready through being cleaned up reduce towards the appropriate shapes and size. After that, the epoxy material is combined with a hardener towards trigger it produce a chemical response that bonds the fibers with each other. The mix is after that put on the carbon dioxide fiber, typically along with a comb or even spray, delegated treat. The treating opportunity depends upon the kind of item the atmosphere, it is necessary to comply with the manufacturer's directions for the appropriate treating opportunity.

ANJIE's epoxy resin for carbon fiber activities include research development improve use composite materials explore new opportunities applications these materials. Modern construction other fields always require updated technology products. ANJIE's RD team continuously exploring new product innovations well as cost efficient solutions efficient application such materials. company recently developed products often able meet customers' various requirements. team experts assist any issue arise during design implementation projects on site. Online consultation material support visit site, testing arrangements etc. Are provided ANJIE.

customer service quality product assure long-term business collaboration potential customers, resulting becoming repeat clients. ANJIE providing composite materials over 20 years. It ISO9001 certified, ISO14001 Environmentally, ISO45001epoxy resin for carbon fiber, SGS Factory Evaluation Report, CE Mark many other certificates. products produced according international standards compliance parameters product per ASTM. Reviews customers deeply evaluated always respond immediately issues occur during following goods received clients site. Customers ANJIE across globe received range technical assistance. includes dedicated team, product samples, resolving issues high-quality products, ongoing customer service.

company among leading composite material manufacturers exporters. specializes basalt fibers, carbon fibers, aramid fibers epoxy resin for carbon fiber. exports regularly international market. It more 100 patented high tech machines active production line. It a dedicated QC staff experienced labs test products prior every shipment. modern technologies used company ensure supply quality products consistently effectively. It recognized a national leader reward product certifications such ISO, SGS, CE others. When customers seeking Reliable customized supplier products, continuous customer service ANJIE trusted supplier.

Since 2004 ANJIE been producing carbon fibre products, such fiber rebars, geo grids rods, chopped fiber so on. products utilized construction structural reinforcement. company also well-known production carbon fiber 3k carbon aramid, carbon aramid Glass hybrid epoxy resin for carbon fiber, biaxial fibre fabric silica fiber fabric, many more. materials widely used sports, aviation boat, marine many automotive parts manufacturing model. As well these materials it equipped dedicated facilities resin products meet client need. Anjies' wide range composite material caters diverse industries including marine, automotive, aerospace.

Copyright © Haining ANJIE Composite Materials Co., Ltd All Rights Reserved