Fiberglass Chopped - The Strong and Safe Reinforcing Material.

Fiberglass chopped is a material made of tiny materials of cut glass into small pieces. It's a cutting-edge and versatile material has its own advantages when utilized in a variety of applications. This anjie method offers durability strength excellent and it really is much safer than other conventional materials. The benefits shall be discussed by us of using fiberglass chopped, explain just how to use it, and supply home elevators its quality, application, and service.

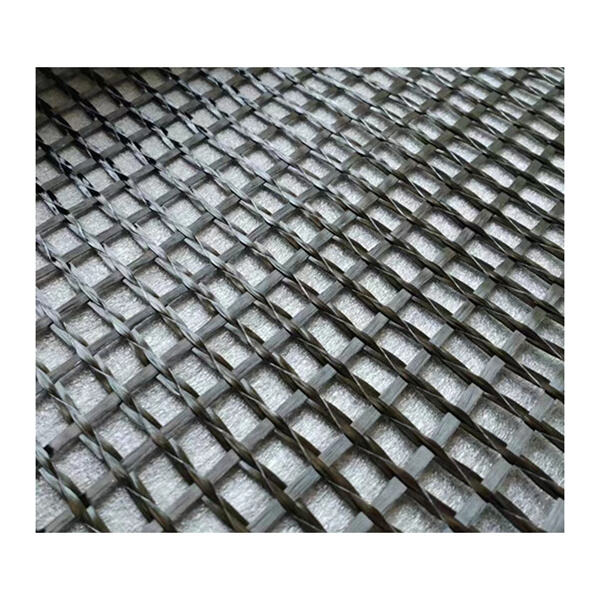

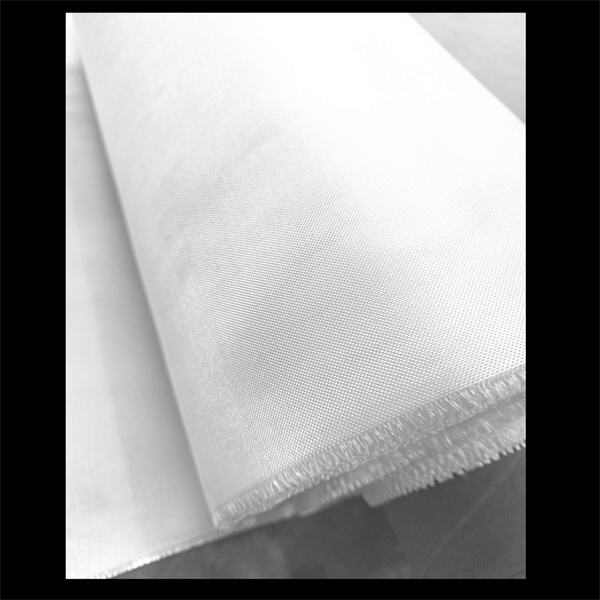

Fiberglass chopped has numerous anjie advantages making it an exceptional material various application. First, it is a lightweight fiberglass construction bars material has excellent strength to weight ratio. Additionally, it is flexible and an easy task to use, making it an ideal material reinforcing other materials. Second, fiberglass chopped is a non-corrosive item which means it does not rust or decay. It's also resistant to chemicals, making it an ideal product use harsh surroundings such as chemical plants. Third, fiberglass chopped is an electrically material non-conductive rendering it safe to use in areas where there is certainly a chance of electrical shock. It could be non-magnetic, making it perfect for used in applications where magnetism might be a challenge.

Fiberglass chopped was a popular material several decades but recent anjie innovations have increased its usability and gratification. As an example, advancements within the production have been enabled by the manufacturing process of smaller and more uniform fibers resulting in higher energy and better consistency regarding the material. New coating technologies have actually already been introduced to improve the bonding of the chopped fibers to other sand coated fiberglass rebar materials, rendering it much easier and more versatile to utilize. In addition, manufacturers are susceptible to chemistries that could be new make the materials easier to process and improve their properties, such as heat flame and resistance.

Fiberglass chopped is a safe material use in varied anjie applications. The process of chopping the glass fibers creates a non-sharp surface and smooth, which eliminates the chance of injury to users during handling or installation. Additionally, fiberglass chopped is non-toxic and won't produce hazardous gases fibers during use or disposal. Moreover, fiberglass chopped is a fire-resistant fiberglass rod material that does not effortlessly ignite or play a role in the spread of flames. Additionally, it is resistant to heat, that makes it perfect for use with in high-temperature environments.

Fiberglass chopped has various utilizes a number of anjie markets are valued in between building, aerospace, aquatic, as well as automobile. It is a suitable product strengthening various other fiberglass reinforcement bar materials, like plastics, cement, as well as steels, creating all of them more powerful as well as a lot more resilient. Into the building market, it is utilized as an enhancing representative cement frameworks like bridges, floorings, as well as wall surfaces. Fiberglass chopped can easily likewise be discovered in the aquatic market towards produce watercrafts as well as private luxury yachts much a lot extra resilient as well as durable. In the automobile as well as aerospace markets, it is utilized towards reduce value as well as enhance the efficiency of compound products.

Customers be pleased high-quality service product. will create long-term relationship company. ANJIE been providing composite materials more 20 years. It ISO9001 certified ISO14001 Environmentally, ISO45001 Health Safety, SGS Factory Evaluation Report, CE Mark many certificates. Products manufactured international standards conform parameters product per fiberglass chopped. Products review clients carefully evaluated take immediate action if problems arise after product delivered client site. Any kind technical assistance a dedicated technical staff including product samples, resolution quality issues, continuous customer service made ANJIE trustworthy clients around globe.

Development research into most modern fiberglass chopped make most composite materials well as explore new applications opportunities such products regular daily activities ANJIE. Modern construction other fields require constant updates technology products. ANJIE RD team always developing new products solutions that cost-effective efficient well as most cost-effective use materials. company recently developed products often meet clients diversified application needs. Additionally, technical experts help resolve any issues may encountered during after projects' construction site. Continuous online consulting well as support materials visits projects/files, arrangements required testing etc. All these provided ANJIE.

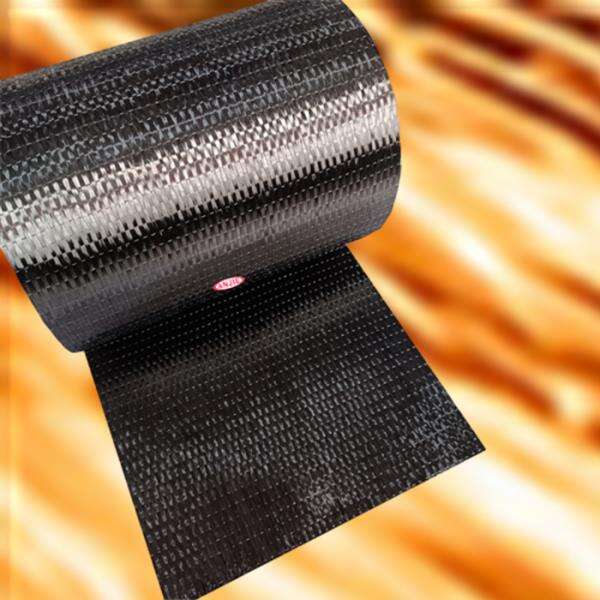

manufactures variety fiber products specifically widely employed fiberglass chopped, construction, automotive, Sports, Wind energy fiber composite-based construction. Since 2004 ANJIE has manufacturing carbon fiber-based products such carbon fiber fabric ud carbon fiber plates geo grids, fiber rebar rod chop fiber, so on. Such materials used construction structural strengthening structural strengthening. It good reputation manufacture 3k carbon fiber, carbon aramid glass hybrid fabric carbon fiber prepreg, biaxial fiber fabric, silica glass fiber fabric numerous others. materials utilized aviation, sports boat, as well many automotive parts manufacturing model. They resin factories meet needs clients requirements. carbon fiber aramid further, ANJIE comprehensive range composite materials suited variety applications across various industries, including aerospace, automotive, marine construction, marine, much more.

One top leading manufacturers exporters composite material, specializes fiberglass chopped, basalt fiber, aramid fibre well as fiberglass products. regular exports international market. AnjIE offers vast selection product lines that produced ANJIE's facilities located Yancheng industrial area Jiangsu province China which covers area 20,000m2. company more than 100 patented high tech machines active production line. company an in-house QC team, as well laboratory qualified staff test products every shipment. latest technologies employed by company ensure able supply high-quality products consistently efficiently. It nationally recognized award product certification organization certifications ISO, SGS CE. When customers seeking established dependable source product, continuous customer service ANJIE trusted supplier.

Copyright © Haining ANJIE Composite Materials Co., Ltd All Rights Reserved