Como Usar Epóxi de Concreto com Segurança e Eficiência para Reparar Rachaduras?

Introdução:

O concreto é apenas um fator vital do projeto de construção, mas não é indestrutível; rachaduras e danos podem ocorrer devido a várias razões, como alterações de temperatura, cargas pesadas e desgaste natural. Felizmente, existe uma solução – Anjie epóxi para concreto para rachaduras . Este artigo explicará o que é epóxi, como ele funciona e, mais importante, como utilizá-lo para reparar rachaduras de forma eficiente e segura.

O epóxi concreto é uma substância de duas partes composta por resina e endurecedor. Quando combinados, eles formam um adesivo durável e forte que pode se ligar a várias superfícies, incluindo concreto, metal e madeira. Anjie epóxi injetável para concreto vem em várias formas, como líquido, pasta e massa, tornando-o versátil para vários tipos de aplicações.

1. Força e Durabilidade: o epóxi pode criar uma junção muito mais forte do que muitos outros adesivos, proporcionando uma reparação de longa duração.

2. Flexibilidade: o epóxi Anjie tem a capacidade de resistir à flexão e curvatura sem rachar ou quebrar.

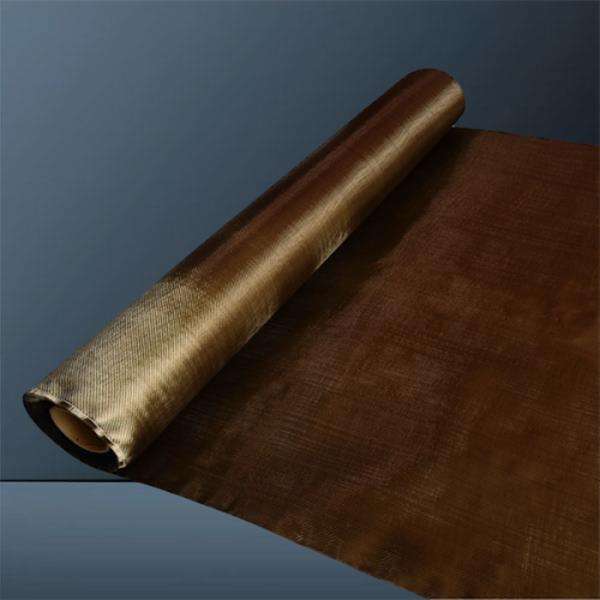

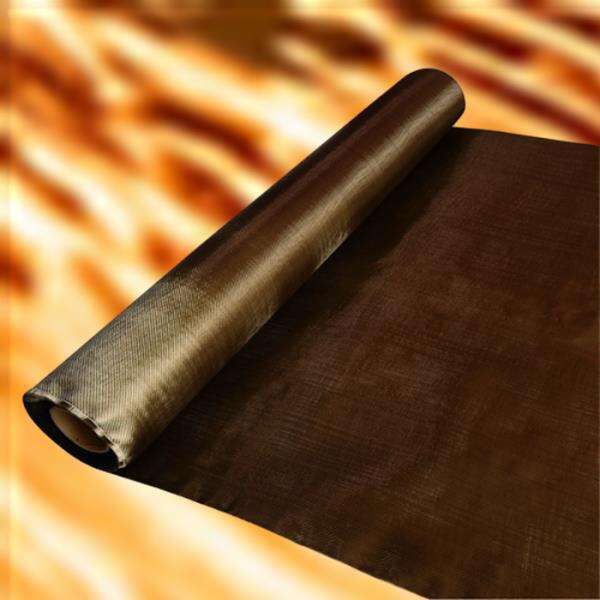

3. Resistência Química: Tecido de resina epóxi de carbono é resistente a vários tipos de produtos químicos que podem danificar o concreto normal.

4. Aparência: o epóxi pode melhorar a aparência da área reparada, fazendo com que pareça nova.

A inovação no epóxi concreto concentrou-se principalmente na melhoria de sua aplicação, segurança e desempenho. Por exemplo, alguns produtos Anjie cola epóxi para concreto os itens estão disponíveis atualmente com proteção UV adicional para evitar o amarelamento ou desbotamento quando expostos à luz solar. As empresas também desenvolveram fórmulas de epóxi que curam em um ritmo mais rápido, e assim as superfícies revestidas ficam prontas para uso mais cedo.

A segurança é vital ao trabalhar com epóxi de concreto da Anjie. Confira a segurança necessária a ser considerada:

1. Sempre use luvas e óculos de proteção ao trabalhar.

2. Trabalhe com superfícies planas e horizontais para evitar derramamentos e misturas irregulares.

3. Garanta uma boa ventilação, pois as emissões de epóxi podem ser perigosas se inaladas.

4. Evite contato da pele com epóxi, o que pode causar irritação e reações alérgicas.

pesquisa e desenvolvimento tecnologias mais recentes maximizam o uso de materiais compostos buscando novas vias para aplicações desses materiais em atividades comuns do cotidiano da ANJIE. A construção moderna em vários campos exige atualizações constantes em tecnologia e produtos. A equipe de P&D da ANJIE está continuamente trabalhando em inovações de produtos que sejam custo-benefício eficientes, bem como em soluções eficazes para a aplicação de materiais. A empresa oferece novos produtos que geralmente atendem aos diversos requisitos dos clientes em relação à aplicação. A equipe de especialistas pode ajudar a resolver quaisquer dificuldades que surgirem durante a construção ou uso de produtos/projetos no local. Consultoria e assistência online ao vivo sobre materiais, epóxi concreto para rachaduras, visitas e arranjos necessários para testes etc. A ANJIE garante que todos os testes necessários sejam realizados.

Desde 2004, a ANJIE vem produzindo produtos de fibra de carbono, como barras de fibra, hastes de geogrids, fibra picada e assim por diante. Os produtos são utilizados no reforço estrutural da construção. A empresa também é bem conhecida pela produção de fibra de carbono 3k, carbono aramida, compósitos de vidro carbono aramida para concreto epóxi em rachaduras, tecido de fibra biaxial, tecido de fibra de sílica e muito mais. Esses materiais são amplamente utilizados em esportes, aviação, barcos, marítimo e muitos componentes automotivos na fabricação de modelos. Além desses materiais, a empresa possui instalações dedicadas para produtos de resina que atendem às necessidades dos clientes. A ampla gama de materiais compostos da Anjies atende a diversas indústrias, incluindo marítima, automotiva e aeroespacial.

Um dos principais fabricantes e exportadores de materiais compostos, especializado em concreto epóxi para rachaduras, fibra de basalto, fibra de aramida, bem como produtos de vidro reforçado. Exporta regularmente para o mercado internacional. A AnjIE oferece uma ampla seleção de linhas de produtos que são produzidas nas instalações da ANJIE, localizadas na área industrial de Yancheng, província de Jiangsu, China, que cobre uma área de 20.000m2. A empresa possui mais de 100 máquinas de alta tecnologia com patente ativa em linha de produção. A empresa conta com uma equipe interna de controle de qualidade, assim como um laboratório com pessoal qualificado para testar os produtos em cada envio. As tecnologias mais recentes empregadas pela empresa garantem a capacidade de fornecer produtos de alta qualidade de forma consistente e eficiente. A empresa é reconhecida nacionalmente por organizações de certificação de produtos com certificações ISO, SGS e CE. Quando os clientes buscam uma fonte estabelecida e confiável de produtos, o atendimento ao cliente contínuo faz da ANJIE um fornecedor de confiança.

epóxi concreto para rachaduras oferecerá produtos de serviço satisfatórios. Isso cria um relacionamento comercial de longo prazo. Com mais de 20 anos de liderança no fornecimento de materiais compostos, a ANJIE está certificada com ISO9001:2015 Qualidade, ISO14001:2015 Meio Ambiente, ISO45001:2018 Segurança, relatório de avaliação da fábrica SGS e marca CE, além de várias outras certificações. Todos os produtos são produzidos de acordo com padrões internacionais e conformam-se com os parâmetros estabelecidos pela ASTM. Avaliações dos clientes sobre os produtos são analisadas minuciosamente e quaisquer problemas que ocorram quando os produtos chegarem ao local do cliente serão resolvidos prontamente. Suporte técnico de qualquer tipo é oferecido por uma equipe técnica dedicada, incluindo amostras de produtos, resolução de problemas e atendimento ao cliente constante, o que torna a ANJIE mais confiável para clientes leais em todo o mundo.

Antes de usar epóxi de concreto, certifique-se de que a área a ser reparada está limpa e livre de detritos. Aqui estão as etapas a seguir:

1. Misture o Resina e o Endurecedor: Misture as duas partes do epóxi de acordo com as instruções do fabricante. Misturar nas proporções corretas é essencial para uma cura adequada.

2. Aplique o epóxi: Depois de misturar o epóxi, coloque-o na área específica que será reparada. Use um pincel ou espátula para espalhar o epóxi.

3. Deixe o Tempo de Cura: Deixe o epóxi curar, o que pode levar de 24 a 48 horas ou mais, dependendo do produto Anjie que você está usando.

O grau do epóxi de concreto Anjie, sua aplicação e uso determinam principalmente o serviço contínuo associado ao produto. Portanto, sua aplicação e uso devem ser realizados habilmente. Sempre consulte um especialista confiável e experiente ou um faça-você-mesmo qualificado para obter conselhos sobre o melhor epóxi para o projeto específico.

A qualidade do produto epóxi Anjie é determinada pela aderência, resistência química, tempo de cura e durabilidade da reparação. Sempre leia a ficha técnica do produto para obter informações sobre o desempenho e qualidade do item.

Copyright © Haining ANJIE Composite Materials Co., Ltd All Rights Reserved