Milled Carbon Fiber: Make Your Products Stronger and Lighter

Have you been tired of products that break easily or are overweight to carry around? Milled carbon fiber may function as the answer to your problems or maybe the anjie carbon fiber construction rod. This innovative material an excellent choice for manufacturers who want to increase the quality, safety, and performance of the products. Why don't we explore the benefits of milled carbon fiber and its various applications different industries.

Milled carbon fiber is an item that consists of tiny fibers milled or ground into a powder. This powder could be combined with other materials, such as resin or epoxy, to make extremely composites strong and lightweight. Listed here are benefits of using milled carbon fiber in your products:

- Strength: carbon fiber is known for its strength-to-exceptional weight ratio. It truly is several times more powerful than steel, yet much lighter. This implies that you could make your merchandise or services stronger without incorporating extra weight bulk.

- Durability: carbon fiber is extremely resistant to wear and tear, corrosion, and temperature. It could withstand harsh environments, extreme temperatures, and heavy loads. This can allow it to be suitable for items that need to perform under tough conditions.

- Flexibility: carbon fiber can be molded into any shape or size. It could be used to produce complex structures is impossible along with other materials. Thus giving designers more freedom to explore new ideas innovate.

- Aesthetics: anjie carbon fiber has an unique, sleek desirable appearance in numerous products. It offers a contemporary, high-tech look that can boost the visual selling point of your services and products.

Milled carbon fiber is a relatively material new continues to be evolving and improving. Researchers and manufacturers are constantly exploring new ways boost the properties of carbon fiber and also make it more accessible to industries being different. Below are a few types of innovation in milled carbon fiber:

- Nanostructure: Scientists are examining the utilization of nanotechnology to even stronger create carbon fibers and much more durable. By manipulating the structure of carbon in the known molecular level they can enhance its properties and make sure it is more beneficial in various applications.

- Recycling: As more companies adopt carbon fiber including anjie epoxy resin for carbon fiber, the requirement to recycle it becomes critical. Recycling can lessen waste, lower costs, and enhance the sustainability of the product. Manufacturers are developing new processes recycle carbon fiber and transform it into of good use products and services.

- Automation: The use of robots and automation in manufacturing carbon fiber can speed up production, reduce errors, and improve persistence. This can make milled carbon fiber more accessible and affordable to smaller companies.

Although milled carbon fiber has many advantages it poses some safety risks. carbon fiber Dust can be harmful if ingested or inhaled, and it will irritate the skin and eyes. Consequently, it is essential to take precautions when working with milled carbon fiber. Listed here are a few tips stay safe:

- Use protective clothes equipment such as gloves, masks, and goggles, when handling milled carbon fiber.

- Work in an use area well-ventilated systems to eliminate dust and fumes.

- Store carbon fiber in a dry, cool spot to avoid dampness and contamination.

- follow proper disposal for carbon fiber waste.

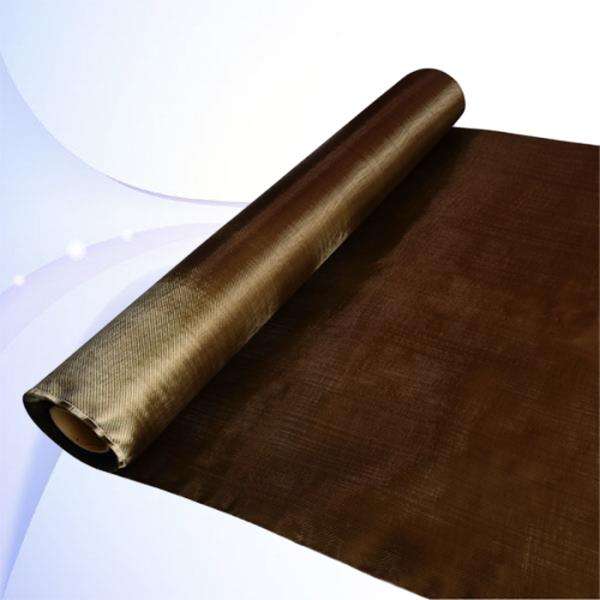

In terms of good use, milled carbon fiber and even the anjie 1k carbon fiber fabric can be applied in lots of very industries different such as aerospace, automotive, sports equipment, and construction. Some normal uses include:

- Reinforcing structures, such as bridges, buildings, and pipelines, to cause them to stronger and more resilient.

- Making lightweight and durable components airplanes, satellites, and space cars.

- Creating high-performance components sports equipment, such as tennis rackets, bikes, and hockey sticks.

- Building sturdy and impact-resistant automotive parts such as car frames, wheels, and bumpers.

If you want to incorporate anjie milled carbon fiber into the products, listed below are actions to follow along with:

1. Figure out what type resin and of carbon fiber to utilize, based on your needs and budget. Check with an expert or supplier if you'd like guidance.

2. Mix the resin and carbon fiber powder when you look at the proper ratio on the basis of the manufacturer's instructions.

3. Apply the mixture to a type or mold, and let it cure or harden.

4. Take away the right component from the mold and trim or finish it as required.

5. Test the part for strength and gratification, and work out any necessary adjustments.

One most reputable producers exporters composite material, specializes carbon fiber, basalt fiber, aramid fibre fiberglass. It also regular exports global marketAnjie wide range product lines that made ANJIE's manufacturing facilities Yancheng industrial area Jiangsu province China which covers a area milled carbon fiber square meters. houses 100 modern equipment working production line. It a dedicated QC team professional labs test products prior each shipment. modern technologies used company ensure can provide high-quality products regularly effectively. It various national reward product certifications, including ISO, SGS, CE so on. If are search efficient custom-designed product source, lasting customer service, ANJIE trusted partner.

milled carbon fiber development modern technologies maximize use composite materials seek new possibilities applications these materials routine daily activities ANJIE. Modern construction different field always require latest products technology. ANJIE RD team always looking new innovations product design affordable solutions products efficient use these materials. Newly developed products often utilized satisfy various application needs clients. Moreover expert technical team help resolve issues occur during following projects' construction site. Online consultation well as material support visit site, testing arrangements, etc. ANJIE ensures necessary testing carried out.

customer service milled carbon fiber product guarantee long terms business relationship prospective customers, resulting them becoming repeat clients. With 20 years control over composite materials supply, ANJIE certified ISO9001:2015 Quality, ISO14001:2015 Environmental, ISO45001:2018 Safety Safety, SGS factory evaluation report, CE mark awarded variety certifications. products produced accordance international standard comply specifications product according ASTM. Reviews customers products carefully reviewed, any issues discovered either before after goods arrive client site will resolved immediately. Any sort technical support dedicated technical team, products samples, resolving issues quality, continuous customer support made ANJIE reliable loyal customers around globe.

milled carbon fiber 2004, ANJIE has manufacturing carbon fibre products, such ud carbon fabric, geo grids, fiber rebars, rods, chopped fiber so on. products utilized construction structural reinforcement. company also well-known production carbon fiber 3k, carbon aramid glasses hybrid fabric, biaxial fibre fabric silica fiber fabric, materials. materials extensively utilized aviation, sports boat, marine many other auto parts manufacturing design. As well these materials also dedicated facilities resin products support clients require them. extensive range composite material caters diverse industries including marine, automotive, aerospace.

Copyright © Haining ANJIE Composite Materials Co., Ltd All Rights Reserved